Mist Collectors

Cleaner, Safer Machining Operations

In metalworking and wet machining processes the oils and coolants used will pollute the work atmosphere in the form of mist. Left unmanaged, this mist collects on floors, walls, work surfaces, and equipment, creating an unpleasant environment that is unhealthy and unsafe for workers.

Equipment can also be damaged by oil and coolant accumulation. Cardinal Air is your source for mist collection solutions for the effective management of submicronic mist contaminants.

Mist Collectors Designed for Reliability and Performance

Cardinal Air offers you the advantage of extensive experience and expertise in developing mist collection solutions. In addition to bringing you advanced mist collection technology from Superior, we provide you with knowledgeable guidance in developing the most efficient mist collector solution to meet your specific needs and challenges.

Aeroex MF550 Mist Collector

Mist Collectors

- MF-550 Universal Mount

FEATURES

- Flexible mounting option

- Can be top mounted on CNC machine to save floor space

- Three Stage Filtration

- Up to 99.7% efficiency

SPECIFICATIONS

- Footprint – 15″Lx15″Wx26″H

- Filtration – (1) mechanical element, (1) agglomerator filter (or (1) demister element for oil applications), (1) Fiber-bed filter

- Airflow – 500-600 CFM

- Motor/Blower – .75 HP Direct Drive Motor

- Voltage – 115v or 220/230/460 3 phase

- Sound – 68 db(A)

- Weight – 50 lbs

- Coolant – 30-3000 psi

- Oil – 30-3000 psi

- Inlet – 6″Ø

- HEPA Filter – Optional

APPLICATIONS

- CNC Machining

- Milling

- Oil mist filtration

- Boring with straight oil, water soluble coolants, hydraulic fluid

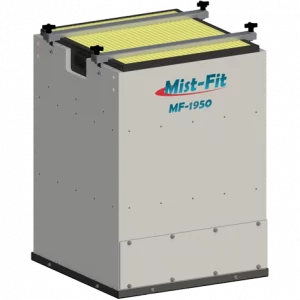

- MF-1950 Universal Mount

FEATURES

- Flexible mounting option

- Can be top mounted on CNC machine to save floor space

- Three Stage Filtration

- Up to 99.7% efficiency

SPECIFICATIONS

- Footprint – 25″Lx25″Wx36″H

- Filtration – (1) mechanical element, (1) agglomerator filter (or (1) demister element for oil applications), (1) Fiber-bed filter

- Airflow – 1900-2000 CFM

- Motor/Blower – 3 HP Direct Drive Motor

- Voltage – 230v/460v 3 phase

- Sound – 72 db(A)

- Weight – 270 lbs

- Coolant – 30-3000 psi

- Oil – Not Recommended

- Inlet – 12″Ø (optional dual 8″Ø inlet baseplate)

- HEPA Filter – Optional

APPLICATIONS

- CNC Machining

- Milling

- Boring with water soluble coolants, hydraulic fluid

- Mist Fit Exploded View

1. The Mechanical Element separates up to 90%

of the oil mist and swarf. The smooth metal surfaces quickly drains fluid

back to the sump.2. The Demister Element supports the 1st stage to ensure up to

95% of the mist and swarf are removed with washable filters.

This is replaced by an agglomerator filter for coolant applications.3. The Fibre Bed mist filter is depth loading that captures small mist

particles. With a filter rating of MERV 15, it can be used without a HEPA

filter on most applications.

Typical life 1 – 3 years.4. Optional –The HEPA filter captures sub-micron mist smoke and bacteria. Our standard HEPA filter is 95% @ 0.3 μm efficient. A higher efficiency filter rated 99.97% @ 0.3 μm is optional.

Typical life 2 – 4 years

HEPA filter is made with exclusive heavy-duty filter media, no other product holds as much or lasts as long.5. Optional – The Pre-Filter Box for oil and heavy mist.

Recommended for Swiss screw machines. Extends filter life many times.

- ARO 4000

FEATURES

- Designed to handle multiple machines

- Three Stage Filtration

- Up to 99.7% efficiency

- Filters coolant and oil

- Filters up to 4,000 CFM

- ARO 4000 Exploded View

Coolant filter stages

- 1.) Mechanical Element

- 2.) Agglomerator Filter

- 3.) Coolant Filter

- 4.) HEPA Filter

Optional

- Odor-Rid Filter

Oil filtration stages

- 1.) Mechanical Element

- 2.) Demister Element

- 3.) #5 Oil Mist Fiber Bed Filter

- 4.) #7 Oil Mist Fiber Bed Filter

- 5.) HEPA Filter

Optional

- Odor-Rid Filter